WHAT IS ARTISJET ROTARY ATTACHMENT?

The artisJet rotary attachment was already introduced in a previous article. artisJet’s cylindrical device is a custom designed attachment for artis BR U1800 A3+ LED UV system, due to the printer’s maximum height adjustment up to 170 mm. The rotary device effectively fits the working area and is attached to the printer’s flatbed. The cylindrical device ensures printing on a multitude of bottle substrate materials and sizes: aluminum, plastic, metal, glass, opaque, transparent, small bottles or wine bottles, any type of bottle that you need to customize by digital LED UV direct printing.

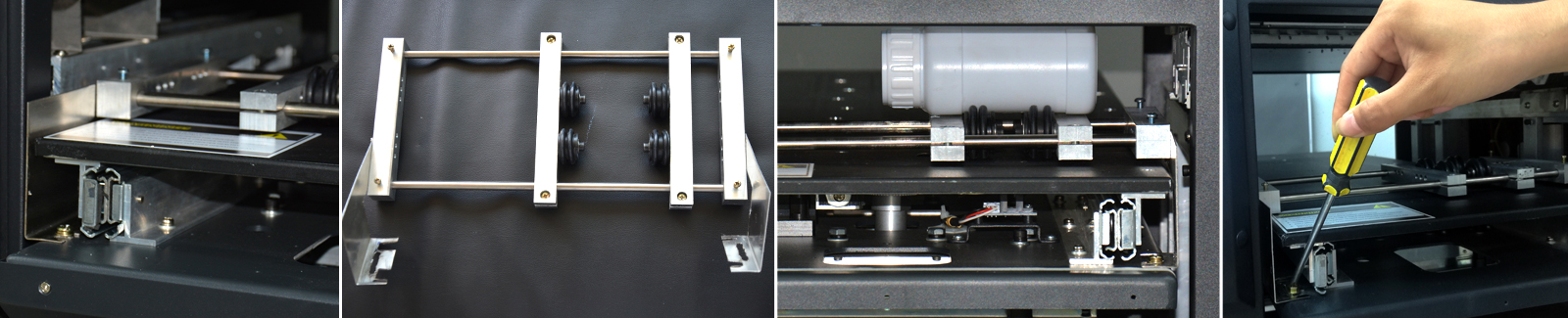

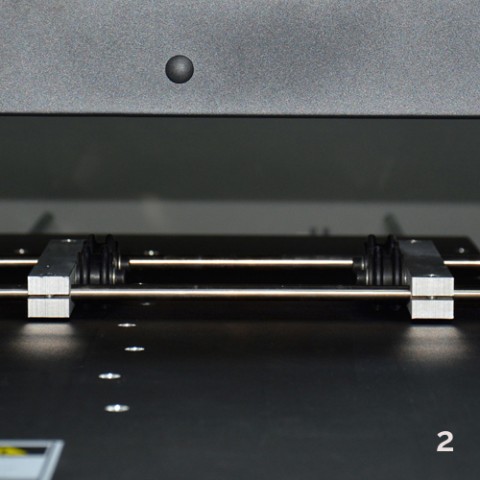

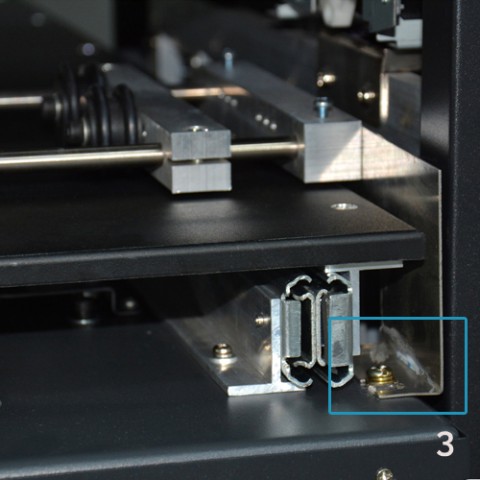

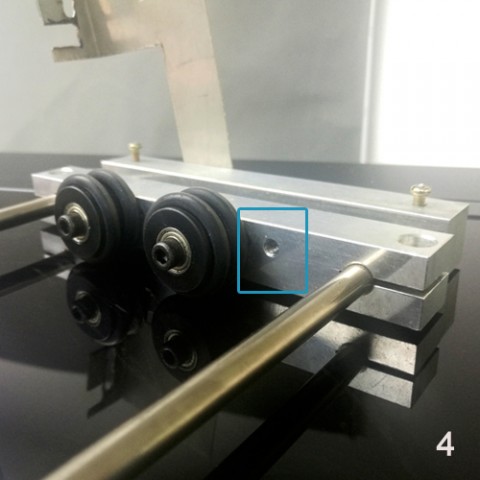

From a technical point of view, the rotary attachment has a simple design, which makes it easy to handle and user-friendly. What makes the bottle media rotate on the device? The artisJet rotary attachment is made of 3 major parts: silicone rollers (1), distance bars (2), and installation ports (3).

Preparation before printing: print principle and key points.

Print on cylindrical products directly with the rotary attachment by rotating the bottles through fixing the rotary jig on the working table. The print area should be regular subjects and the printing area should be the highest point of the bottle. Install the rotary jig correctly as instructed by artisJet user menu.

HOW TO INSTALL THE ROTARY ATTACHMENT?

There are 4 silicone rollers on the rotary attachment. These silicone rollers are the ones that drive the substrates to be printed through the friction force.

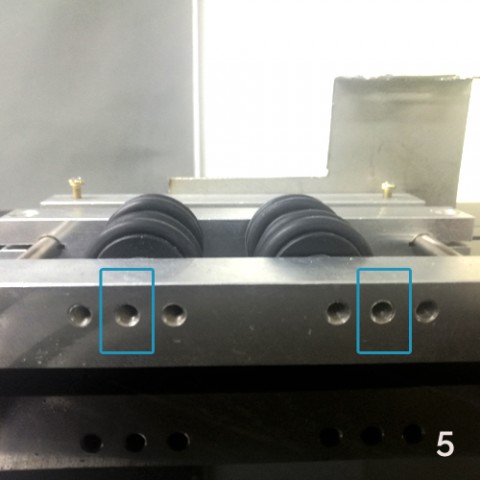

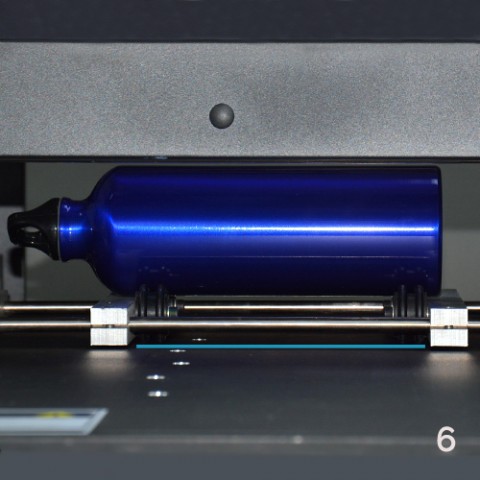

The four silicone rollers are fixed through the screw holes (4). It can be easily adjusted for different positions (5), depending on the bottle diameter. All four silicone rollers shall evenly reach the flatbed and rotate smoothly as the flatbed moves (6).

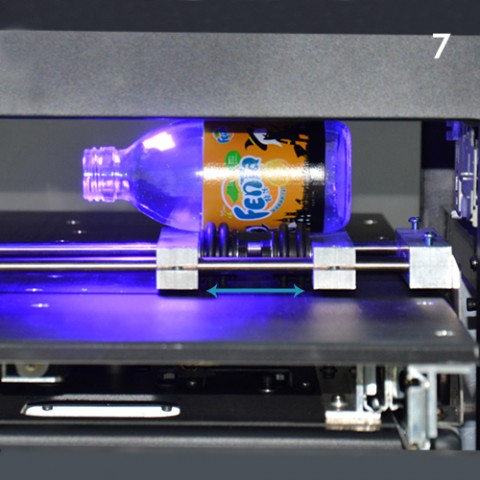

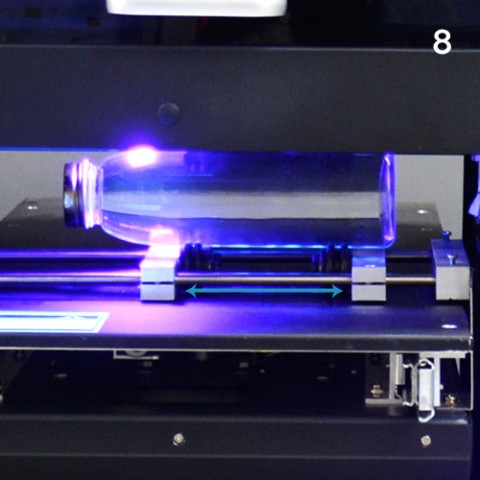

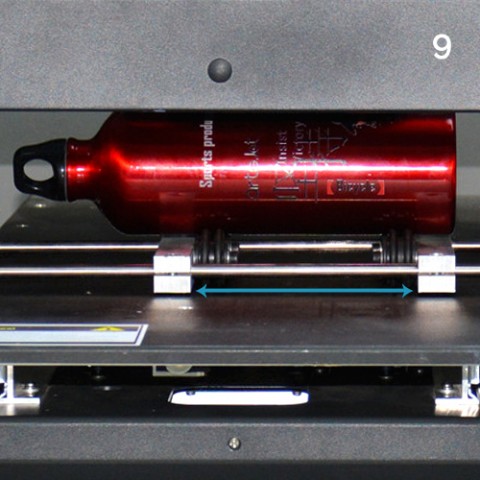

Custom LED UV rotary printing with artis BR U1800 accommodates cylindrical objects with a maximum print bottle diameter of 8 cm (3.15 inches) and a maximum printable bottle length of 32 cm (12.6 inches). Therefore, the distance bar it is for different sizes of bottles and it can be adjusted based on each bottle length for printing on demand: small (7), medium (8) or big (9), up to 32 cm in length.

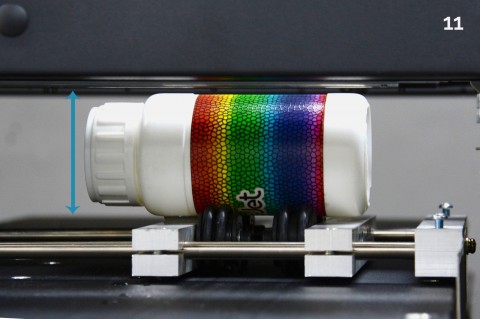

The installation port is applied for the right installation of the rotary attachment. The first step is to adjust the position of the rotary attachment by fixing the four rollers through different screw holes (5). Second step implies moving the printer’s flatbed back and forth after fixing the rotary attachment in order to ensure that all four rollers rotate smoothly. If not, the rotary attachment shall be adjusted to ensure this (6).

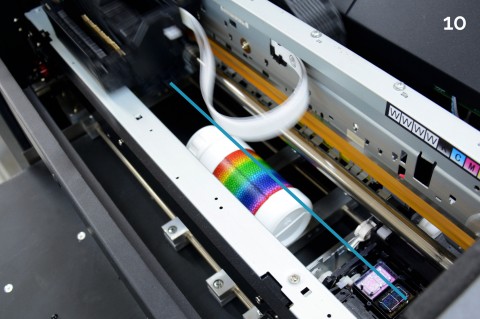

How to be sure the rotation will be smooth? Put the media on the rollers and ensure the line at the highest point of the media shall be distanced about 5 mm away from the back center line of the ink pump (11). This is necessary to follow in order to avoid ink spray from the print head when printing on the arc of the bottles (10).

The artisJet rotary attachment is installed. The only thing that needs to be done is to set the software for the design of choice and start the print job of the first bottle with artisJet digital LED UV direct printing solutions.

Watch this video for 360 degree full cylinder printing on small plastic bottle, using the artisJet rotary attachment custom made for artis BR U18700 A3+ LED UV printer.