All the printers will encounter problems from time to time when printing day in and day out. In order to achieve durable printing life span and highest quality your printer can produce, consistency is the main key. It is important to keep the print head in top condition and the easiest way of doing this is by simply running a test print or a nozzle check every time before printing. This way you can follow the state of your print head and find out if a cleaning is needed.

Clogged nozzles can cause many printing issues. By doing a nozzle check on a daily basis insures that you are always aware of the current state of your printer’s performance.

What to do if the printer head is clogged? In a previous article, we presented some of the reasons the printer head can clog. The printer head is always the most cost part in a printer and it is a big headache for all the LED UV printer users if they are facing the problem. Before we think about how to clean the clogged head, we have to know if the printer head is really clogged.

But how to judge if the printer head is clogged becomes an essential

question.

If you find that the printed image is unexpectedly faint or dots in the

printed image are missing, you may be able to identify the problem by

checking the print head nozzles. You can check the print head nozzle from

your computer using the Nozzle Check utility in the printer software or from

the printer itself.

Sometimes, even with a perfect nozzle check, the problem cannot be solved

and this can be for several reasons.

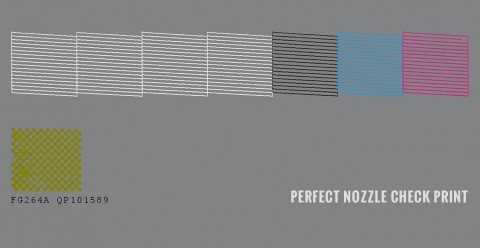

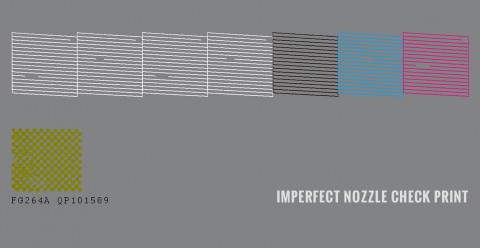

Problem: When doing a nozzle check, the color stripes are

supposed to be fully printed, with no interruption in the lines, but

sometimes there are some gaps in the nozzle check (as in the image below)

even after several software Head Cleaning and Automatic Cleaning were done

already.

When your nozzle check is the same as the one in the picture, DO NOT go directly to treat it as the printer head is clogged!

Follow the right steps to solve the nozzle check problem.

Step 1 – ink level check. Check if there is enough ink in

the ink bottles by opening the ink tanks. Refill ink if the ink tube port is

already above the ink level. After this, proceed by doing the PRINTER HEAD

CLEANING from the software or printer driver.

If the problem persists, try the second step.

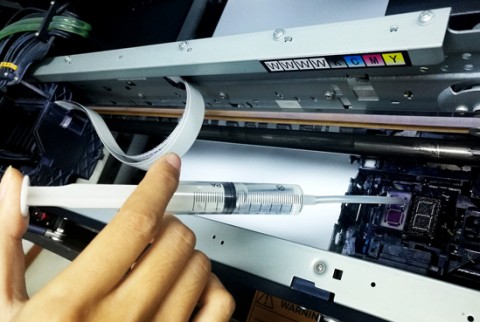

Step 2 – Cap Top situation diagnose. Take the ink

maintenance syringe and suction from the waste ink tank tube. By doing this,

you can encounter several states of the problem.

Firstly, the cap top is in good situation if you can take the inks out easily with some pressure and feel the vacuum well. Then you do not have to practice the following steps but make nozzle check directly again.

Secondly, if you cannot feel the vacuum at all and there is air leaking sound when suction the ink, it means that you are dealing with a cap top malfunction and this requires replacement. The reason? As time goes by, the sponge in the cap top will be melted gradually by the solvents in the ink.

Another reason is that the cap top may be clogged if you cannot drag the syringe and you feel strong vacuum. What to do? Pour the cleaning solution onto the cap top sponge and wait for 10 minutes and suction again until the cap top is in the good situation as mentioned above.

Continue and make nozzle check again. If the nozzle check is good it means the problem is solved. But, if the nozzle check still is not good, then proceed on the following steps.

Step 3 – Damper situation diagnose. Take out the damper,

the one for the color which nozzle line is not good from the carriage. If

the damper is normal, then you can suction the ink into the syringe.

The damper will need replacement if you cannot get the ink out or it gets

out too little but with big pressure as the damper is clogged itself.

Finally, if the imperfect nozzle check still exists, then the problem will

be from the printer head!

How to unclog the printer head? One mean is by manual cleaning with cleaning

liquid. If the manual cleaning still cannot solve the problem, clean the

head by ultrasonic device.