What sets a UV LED printer apart from different printing technologies is the unique UV curing technology. What is UV curing technology? UV curing is a photopolymerization process that uses UV energy to change a liquid to a solid. The UV LED printing technology refer to a non-impact, inkjet printing technique that instantly cures or dries jetted ink droplets directly onto the printable substrate. It’s amazing what a single UV LED printer can produce.

A LED UV print system gives the possibility to print on various materials, such as plastic, and on different kind of products: plastic items, acrylic awards, small plastic desktop signs, plastic watt meters and industrial labels, acrylic key chains, plastic packaging, custom plastic cards, plastic blank media cases for CD and DVD covers, plastic smartphone accessories to many other plastic derivatives items.

The ability to function at optimum levels, even during long-lasting and high volume printing jobs with consistent quality output, makes UV LED technology an effective printing solution. However, it can happen sometimes to experience a print failure even on a seemingly working system.

Which are the common problems of UV LED digital direct plastic printer for long-term run? Two main factors of the UV LED print system that might affect the clean and clear plastic prints:

The flying inks which will stain the materials with some small ink droplets. All of the digital printers are delivering the colors by piezoelectric technology which is firing, shooting out, and instantly solidifying the inks during the direct printing on the substrates. However, there are some ink droplets randomly spraying or splashing due to the air while the printer is on. This will create dust and make the ink system dirty and the print head also. This could shorten the printer head durability.

The static electricity from materials which will over spray the artwork. Surface static charge is also the cause of many common printing defects. What’s causing the static electricity and ink over spraying? The power of the static electricity interferes with the ink direction while printing, pulling the ink particles away from their intended trajectories causing printing defects including over spray. Static electricity is generated by an unbalance between the molecular construction of relatively non – conductive insulators such as plastics, paper, glass, ceramics and other non – conductive materials. Not only can these particles land in the wrong places, but they can also be pulled back toward the printhead, which can cause clogging of the printhead.

HOW ARTISJET SOLVES THE ABOVE FACTS AND WHICH ARE THE BENEFITS?

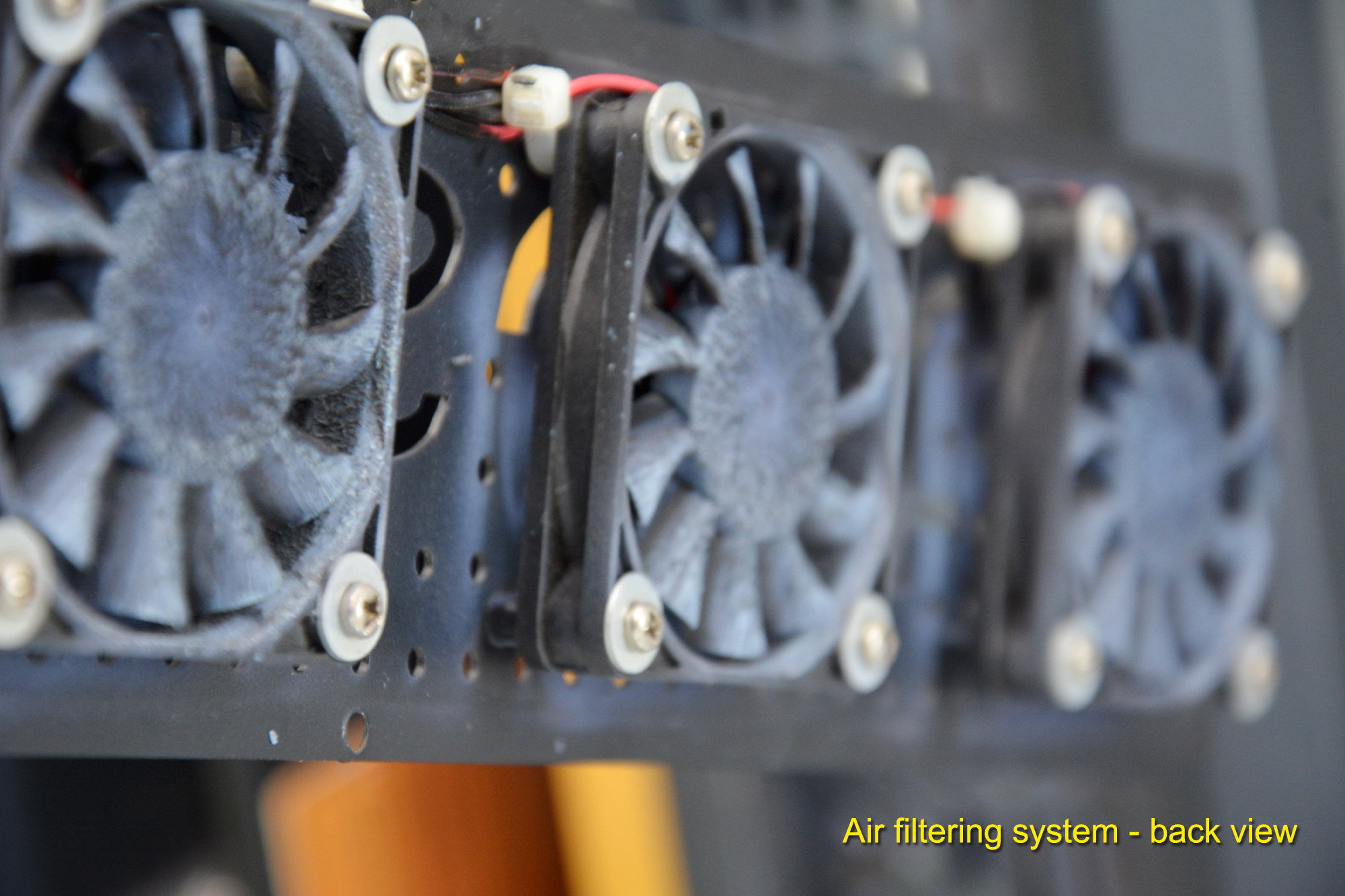

Filtering system to absorb the floating droplets to eliminate the ink dust. Equipped with a professional filtering system near to the carriage (about 7 cm), the artisJet digital UV LED direct plastic printers are minimizing the dust generated by the inks. This translates into longer life of the whole ink system and delivering clean and clear prints.

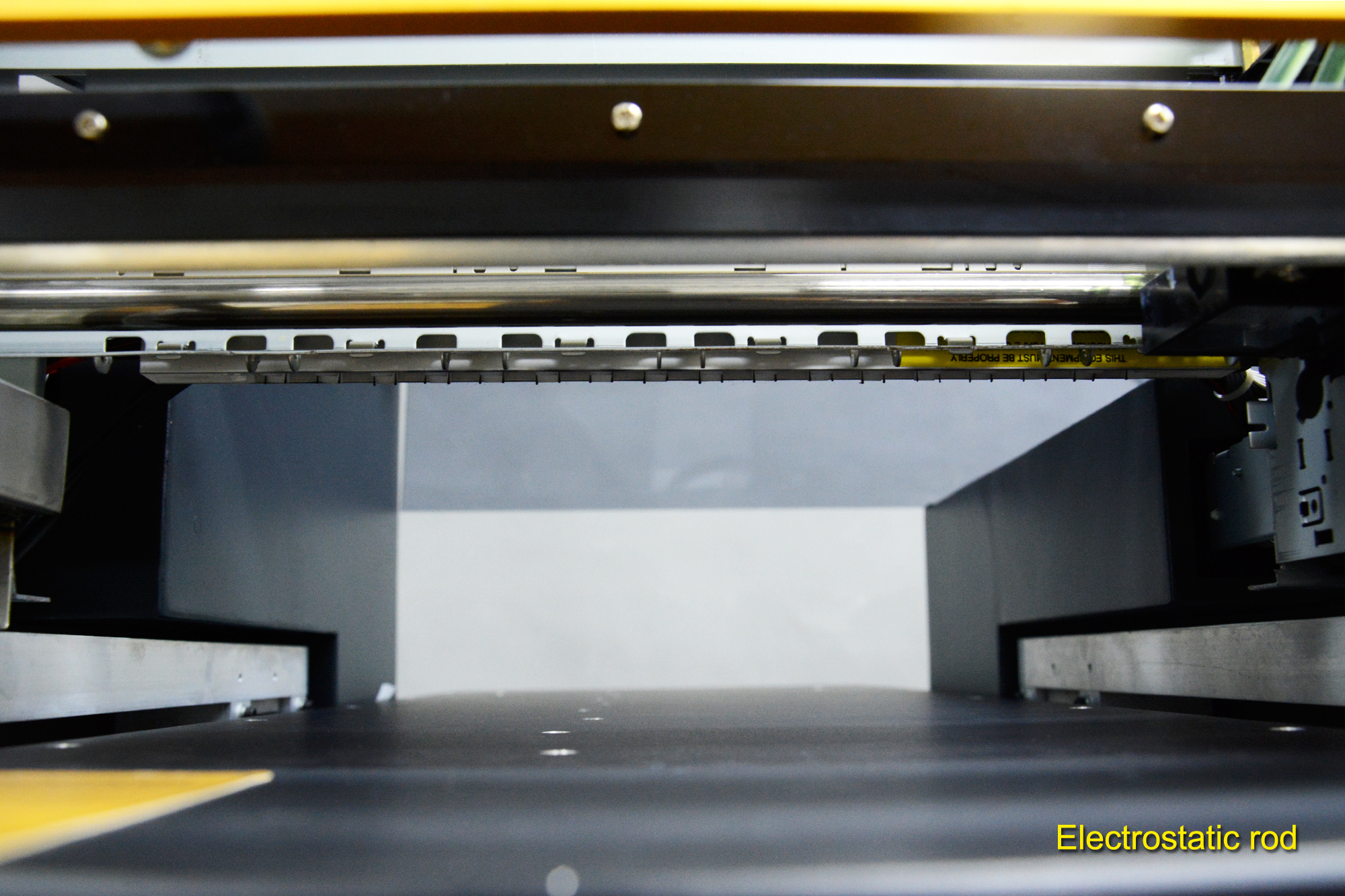

Anti – static system to neutralize the electricity from the materials and ensure the 100% ink droplets direction. Installed in the materials loading port 2 cm before the start of printing, artisJet electrostatic rods can produce a large number of positive and negative air mass charges, through ion radiation area of the object on the charge and then neutralize it. When the surface of the object is negatively charged, it will attract the positive charge in the radiation area; when the surface is positively charged, it will attract the negative charge in the radiation area so that the surface of the static electricity is neutralized.

UV LED systems require very little space and are easy to integrate into small spaces. The UV LED printers produce no ozone emissions or hazardous waste concerns, which makes it eco-friendly printers and safe to operate even in crowded places such as public print shops, digital stores, shopping mall kiosks etc.

Don’t let over spraying, dust and static electricity interfere with the printing workflow and lower the production. Fortunately, there are solutions for taming and removing these aspects while printing. Just find which artisJet UV LED flatbed printer is suitable for you and what works best to meet your printing requirements.

Want to know more about direct plastic printing and other printing solutions from artisJet UV LED print systems? Reach us by direct message on available social media platforms: artisJet Solutions, artisJet Technology, Instagram, Twitter, Pinterest, fill in the contact form or simply e-mail us by This email address is being protected from spambots. You need JavaScript enabled to view it..

Feel free to request a sample to discover the printing capabilities of artisJet digital direct printing systems.

Subscribe to artisJet YouTube channel for printing solutions videos, learn how to use artisJet printing software to achieve different outstanding print effects, discover video testimonials and maintenance video support to much more.