artisJet supports its customers and products

Larson Meter Craft | Santee, California, USA | www.larsonmetercraft.com

Challenge

We are a manufactory of graphics in USA with long history and well known in this area. Before we knew about flatbed printer, we had used offset printing on our products, it’s very expensive. From year 2007, we tried to find an economic printing method.

Solution

We found and contacted with artisJet and we have sent materials to them to print samples for us. We were very happy with the printed samples so we decided to buy it. We had some concerns with the overseas deal, especially 100% T/T in advance, but during 1-2 months’ communication, the professional answers and service of my sales representative convinced me. I trusted them. Then everything went smooth, we placed the order, made payments and bought machines by express. As they have goods in stock, they send the printer around 4-5 days, and it took about 3-4 days to arrive at our company by express. The Machine is very easy to use. The BR-1400 is based on the EPSON Photo Stylus 1400… It uses a 6-color print head (Yellow, Black, Light Cyan, Light Magenta, Magenta, Cyan). When you install the printer you actually install the factory Epson drivers. This is helpful because the computer treats the printer as a standard Epson inkjet printer. This frees you up to use any graphical program you want to use and you are not locked into using some proprietary plotting software. For example, I commonly print using AutoCAD, Photoshop, and CorelDraw. You can print using anything you want basically, even Microsoft word if you want.

Results

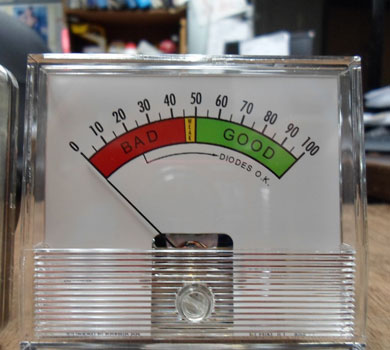

I use my BR-1400 daily and for what I do in my industry, it has saved me countless hours and most importantly DOLLARS from my old method of offset or silk-screen printing. Not only can I now go from concept to finish part within minutes verses hours, I also gained the ability of offering photograph quality logos and pictures to my customers. I couldn’t do that before because I did not get the proper color tones and shading with offset printing. My cost per part also went down. I now print my digital image from AutoCAD and Photoshop straight to finish part without needing to do any pre or post coating to the material and it dries in seconds! Before, I would have had to print the artwork out on paper, then make a negative, then make a printing plate, then print the part with an offset press, and finally wait for the ink to dry… easily taking hours to complete plus the cost of film, printing plate, developing chemicals, and ink… The machine is very helpful, we become a very unique supplier specialized in making the products no one else will. Some of my friends were very interested in it for their business, so I help them to bought flatbed printers. I started doing business with artisJet over 8 years ago, until now I have bought and resold between 8 and 10 printers here in the United States along with consumables like inks and artisJet printers that are widely used in instrument face and meter dials printing in USA now. As for support, I have known the company and have developed friendships with them for over 8 years and when I have had any questions or problems my rep was on top of it. If I needed answers I got them next business day (because of the 15hr time difference). If I had warrantied broken parts, they were sent out quickly and at no cost to me, If I needed training my rep was able to email, call, and Skype with me at my time of business even if it was 2:00am in China. I cannot say enough about how they support their product and customers.