ArtisJet Blog

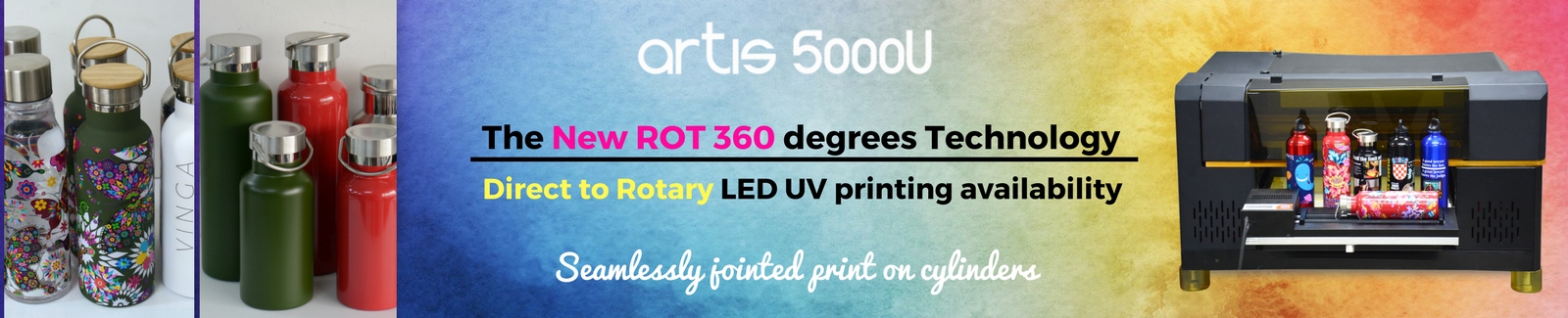

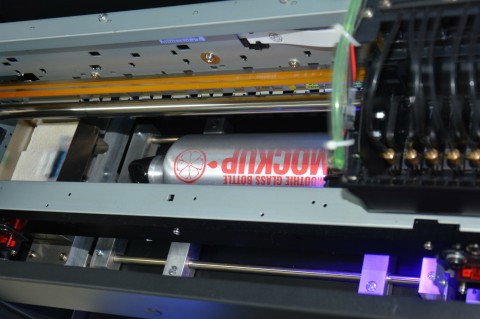

Custom LED UV rotary printing enables you to personalize the look of your products without making use of any additional paper labels. The most innovative way to finish, personalize and decorate cylindrical objects, bottles, some jars shapes, and packaging is the LED UV printing technology.

Many customers have asked about the print option on cylindrical objects with the artis 5000U A2+ LED UV printer. That is why artisJet took the time to create an effective cylindrical device, the new rotary jig for artis 5000U. The wait is finally over. artisJet is launching its new rotary attachment for artis 5000U.

Discover artisjet’s solutions to print on bottles and cylindrical objects, and enter into the new era of creating personalized special products.

BENEFITS OF PRINTING WITH THE NEW ROT 360 DEGREES TECHNOLOGY

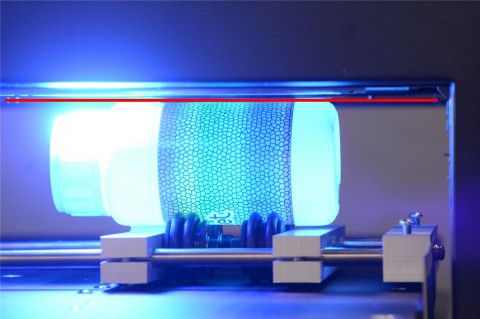

The advantages are easy to figure out. One of them is the ability to directly print multiple colors at high speed and without heavy metals using a quick, simple and low-cost curing process. LED UV light provides exactly this! These solutions enable users to process a variety of materials at maximum production speeds, with low-input power requirements. Produce branded and personalized bottles and other cylindrical items quickly and easily and make use of artis 5000U with the new rotary jig.

Check the ROT 360 degrees device highlights:

1. 360 degrees printing on a wide range of cylindrical products and

materials: direct print on wine bottles, tea cans, cylindrical packaging,

wax candles, aluminum bottles, steel tumblers, stainless steel cups, glass

drink ware to much more.

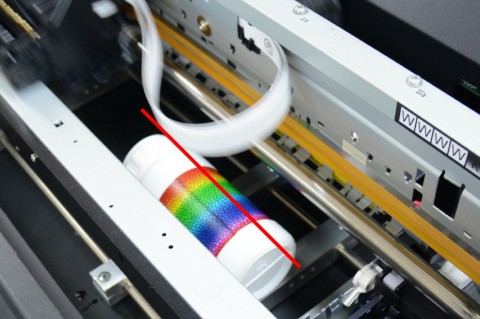

2. ROT offers accurate and vivid prints benefiting from its motorized driven

system.

3. With the latest artisRIP V9.0 software and ROT Print Manager, enable

color and white printing in one pass directly on all colors substrates

(black, transparent, dark, glossy)

4. Empowered by artisJet DTS3 LED UV ink technology, ROT 360 degrees enables

rich and sharp color performances.

5. Realize full 360 degrees continuous spin jointed seamlessly on cylinders.

6. Go Green and ECO with the lowest power consumption to 30W.

artis 5000U flatbed LED UV

printer delivers bottle printing capabilities to your business, so that you

can easily introduce 360° cylindrical printing to produce

printed water bottles, personalized bottles, gift bottles and much more.

artisJet digital

printing on cylindrical and round objects such as bottles

gives you UNLIMITED substrate color choices both white and

full color prints on all colors.

WHAT CAN YOU PRINT WITH ARTISJET PRINTING SOLUTION FOR CYLINDRICAL ITEMS?

You can print a diverse range of bottle substrates such as: plastic, PET, metal, aluminum, stainless steel, glass, ceramic, and any other material that has a cylindrical and rounded shape. There are various bottle types you can print like wine bottle, water bottle, baby bottle and storage bottle.

Flexible and reliable, artis 5000U LED UV printer designed for small environments is the perfect choice for top quality products requiring vivid, brilliant, and high-definition printing.

Choose from a large variety of ideas: custom drink ware printing , custom metal water bottles printing, aluminum bike bottles printing, baby bottles, metallic sports bottles printing , aluminum cans printing, wedding glass bottles printing, wine bottles printing , gift bottles printing, candy bottles, cosmetic bottles, jars, decorating bottles for interior design, candles, candle holders, personalized products for holidays, food rounded cylindrical packaging, decorative bottles to much more.

WHAT ARE ARTISJET`S ROT 360 DEGREES PRINTING SPECIFICATIONS?

Custom LED UV rotary printing with artis 5000U accommodates cylindrical objects with a maximum print bottle diameter of 7.6 cm and a minimum print diameter of 5.7 cm.

Print the full circumference of the bottle within minutes. For a full size image printing (139.2146 mm * 208.7 mm), an 8 pass print resolution, and white and color simultaneous printing, you can achieve full bottle diameter coverage with rotary jig and artis 5000U LED UV system, within 10 minutes printing time.

HOW TO USE THE ROT 360 DEGREES ROTARY DEVICE WITH ARTIS 5000U PRINTER?

Printing on cylindrical objects such as bottles has never been easier. From the placement of the jig on the flatbed and till the final printed cylindrical object, the new bottle printing jig of artis 5000U requires few easy-to-follow steps to enhance your workflow.

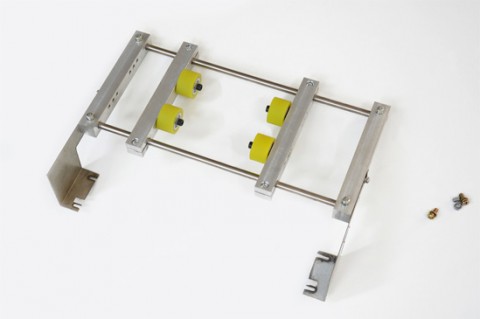

From a technical point of view, the rotary attachment has a simple design, which makes it easy to handle and user-friendly. The first step is to fix the rotary jig on the table and connect the power line with printer. When the printing is starting the bottle is moving the rotary jig by motor of rotary instead of flatbed movement. After setting all the printing options according to the printing needs, just manually place the cylindrical bottle on the artisJet device and press print.

The ROT 360 degrees rotary device effectively fits the working area and is attached to the printer’s flatbed. (20 x 40.2 x 7.2 cm). The new rotary attachment device customized for bottle printing with artis 5000U A2+ LED UV printer is available in two colors, on demand: black metal rotary jig and gold metallic rotary jig.

Interested in cylindrical and bottle printing with ROT 360 degrees technology?

Ask for artis 5000U’s custom rotary device ROT 360 by e-mail to This email address is being protected from spambots. You need JavaScript enabled to view it. and enhance the printing capabilities of your business.

Stay connected to artisjet for upcoming news! We are on Facebook, Twitter and Instagram! Like, follow and join us online to make sure you stay updated with details on upcoming news, events and our printers, direct to substrate printing solutions, and technology.

Bottle printing is a popular choice because the end result is durable, versatile, and attractive. Direct to substrate printed bottles doesn’t alter your brand, it enhances it!

360 degrees LED UV direct to substrate printing technology eliminates the need for label substrates, promising to be the next generation variable data printing solution for innovative bottle designs and consumer engagement.

One of artisJet’s cylindrical devices is a custom designed attachment for artis BR U1800 A3+ LED UV printer. The rotary device effectively fits the working area and is attached to the printer’s flatbed.

TECHNICAL SPECIFICATIONS - WHAT`S NEW ABOUT THIS ROTARY DEVICE?

Custom LED UV rotary printing with artis BR U1800 accommodates cylindrical objects with a maximum print cylinder diameter of 14 cm (a cardboard tea box, for example) and a minimum print diameter of 5 cm.

The updated rotary system with silicone rollers contributes to printing perfection! The silicone rollers offer enhanced stability and liability of the cylindrical item, perfect and easy adjustment and setup on the flatbed.

The silicone rubber rollers are used in a variety of applications including banding, laminating, printing and decorating. Carefully engineered and crafted, the silicone rollers allow specifically match of your cylindrical applications.

There are a few characteristics of software settings: printing resolution of 1440*1440 dpi for a fully printed artwork and design; print effect types: Color only, White & Color only, White & Color printed simultaneously.

A full size image / graphics / design printed with rotary jig with a resolution of 1440*1440 dpi you can print it in 12 minutes (imagine size 200 mm*110 mm). Simply select the desired artwork size and preferred color settings, load your product into the rotary fixture and you’re ready to print.

BENEFITS OF 360 DEGREES PRINTING WITH THE UPDATED JIG FOR ARTIS BR U1800

We believe glass bottle printing is an art. The rotary device allows you to differentiate yourself from all the paper-labeled bottles on the shelf. Custom bottle printing just got easier! Whether you are looking to print your own professional wine bottles or you want your logo on a stainless steel bottle, you will need the capability to print on cylindrical shape and delicate materials.

The process is simplified – all you need to do is to print direct to substrate.

The cylindrical device ensures printing on a multitude of cylindrical objects substrate materials and sizes: aluminum, plastic, metal, glass, opaque, transparent, small bottles or wine bottles, any type of bottle that you need to customize by digital LED UV direct printing. You can print a diverse range of bottle types like wine bottle, water bottle, baby bottle, storage bottle and so on.

artis BR U1800 gives you unlimited substrate color choices so you don’t have to settle for only printing on white or light colored cylindrical objects.

Stay connected to artisjet for upcoming news! We are on Facebook, Twitter and Instagram! Like, follow and join us online to make sure you stay updated with details on upcoming news, events and our printers.

Interested in artisJet’s printing solution for your business? Discover more by sending your inquiries to This email address is being protected from spambots. You need JavaScript enabled to view it. or easily use the contact form on artisJet website.

Need some inspiration for your printing project? Such as wine bottles, candy bottles, wedding glass bottles, jars, metallic sports bottles and so on. Have you ever wondered how these items often times have a company logo, customized or personalized design printed on them?

UV LED cured cylindrical printing is an exciting new technology. It allows accurate and fast full-color digital decorating on black, color or clear cylindrical-shaped products. The utilization of UV cured cylindrical printing technology has grown exponentially over the past years.

ARTISJET UV LED PRINTER DEDICATED TO CYLINDRICAL PRINTING APPLICATIONS

artisJet’s rotary device can direct print on cylindrical objects with a full end to end 360 degree spin of the cylindrical product. This way, you can maximize your media surface by printing the entire circumference of it. artisJet’s cylindrical device is a custom designed attachment for the artis BR U1800 A3+ LED UV system, due to the printer’s maximum height adjustment up to 170 mm. The rotary device effectively fits the working area and is attached to the printer’s flatbed. The rotary fixture for flatbed UV printers is easy to install and remove in just a few minutes so that the printer can be used for both cylindrical and flatbed printing on a daily basis.

Custom LED UV rotary printing with artis BR U1800 accommodates cylindrical objects with a maximum print bottle diameter of 8 cm (3.15 inches) and a maximum printable bottle length of 32 cm (12.6 inches), all printed with a resolution of 1440 by 1440 dpi.

You can print a diverse range of bottle substrates such as: plastic, PET, metal, aluminum, stainless steel, glass, ceramic, and any other material that has a cylindrical and rounded shape.

Choose from a large variety of ideas: custom drink ware printing, custom metal water bottles printing, aluminum bike bottles printing, metallic sports bottles printing, aluminum cans printing, wedding glass bottles printing, wine bottles printing, gift bottles printing, candy bottles, cosmetic bottles, jars, decorating bottles for interior design, personalized products for holidays, food rounded packaging.

For example: A printed sports bottle is the kind of product that can be used for promotional purposes. These plastic sports bottles are durable promotional products that are great to hand out at sporting events where drinking beverages or water is required. A custom sports bottle is the type of promotional product that can be handed out to all target markets, because everybody needs to drink and stay hydrated, so just about everyone can make use of a personalized sports bottle.

Understanding the artis BR U1800 print and software

How to print on bottles? Are you ready to get started? Follow these easy to use steps to begin.

artis BR U1800 gives you unlimited substrate color choices so you don’t have to settle for only printing on white or light colored cylindrical objects. Simply select the desired artwork size and preferred color settings, load your product into the rotary fixture and you’re ready to print.

The first step is the adjustment of the rotary attachment (1). Put the media on the rollers and ensure the line at the highest point of the media shall be distanced about 5 mm away from the back of center line of the ink pump. This is necessary to follow to avoid ink spray from the print head when printing on the arc of bottles. The next step is to drive installation of the software for bottle printing.

There are a few characteristics of software setting: The printing resolution is 1440*1440 dpi; Bottle print only refers to three print types: Color only, White & Color only, White & Color simultaneously; (INK: CMYK- Optional for color only; White: Optional for white only or White & Color simultaneously.)

White Mode: It decides the way of printing white ink as a background layer.

artisJet’s RIP software allows the setup of white ink based on the printing requirements. One of these requirements is to: print white inks according to the nature of the bottle’s substrate color (dark or light). The darker the substrate, the more white inks.

Another white ink setup capability is White (Simulate Spot Color): whenever there is color element, white inks will be printed, with the same volume. Add to this, the White Density allows you to adjust the volume of white inks, while the White Channel num can adjust the concentration of the white inks.

White and color relation: This can change print mode for white and color inks. White only: Optional for white only; Two layer: White+ Color print at on pass (color follows White); Two layer: White+ Color print at on pass (White follows Color).

White invaginate: This is capable of covering white edge. Choose “Big” to avoid white edge when printing white and color simultaneously. Make a difference in covering the whole white edge.

For a better understanding we want to show you two cases of printing:

1.White bottle for color only;

2.Transparent bottle for white& color simultaneously.

For first case steps:

a) Measure the circumference of body of bottle and height of artwork. Make the artwork size within the circumference (figure 2).

b) Input the artwork into Rip software and set up its size and location. Pay attention to: print direction and print location. The setup software should have the follow ticks: INK-CMYK; White Invaginate- Big; Feather- Auto.

c) Adjust the height of bottle according to print head (Attention: Adjust manually the height of bottle a little far away from the print head to ensure no collision.)

d) Start printing.

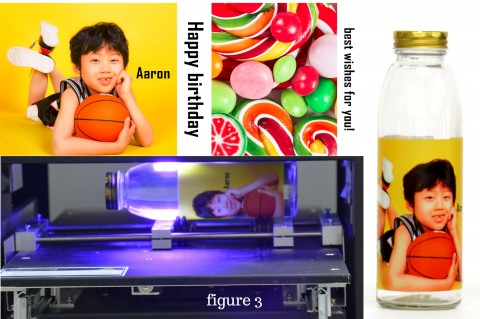

Case 2 (figure 3): same steps less the software setup. You have to choose: Ink- white; white mode- white (simulate spot color); white channel rum-4; white & color relation- two layer, base white.

It’s time to bring your personalized products to life by using amazing, high quality, full vivid colors direct-to-substrate printing with artisJet and its bottle printing attachment of artis BR U1800, 360 degrees printing on a wide range of substrates, user-friendly print settings and functions via artisRIP v 9.0 software.

Do we draw your attention?

artisJet is continuously working to improve your workflow and printing experience. We are excited to announce soon we will come up with a surprising new rotary device for our printers. Bottle printing is a valuable solution for personalization businesses. That is why, artisJet is looking to provide complete direct to substrate printing solutions in one place.

Stay connected to artisjet for upcoming news! We are on Facebook, Twitter and Instagram! Like, follow and join us online to make sure you stay updated with details on upcoming news, events and our printers.

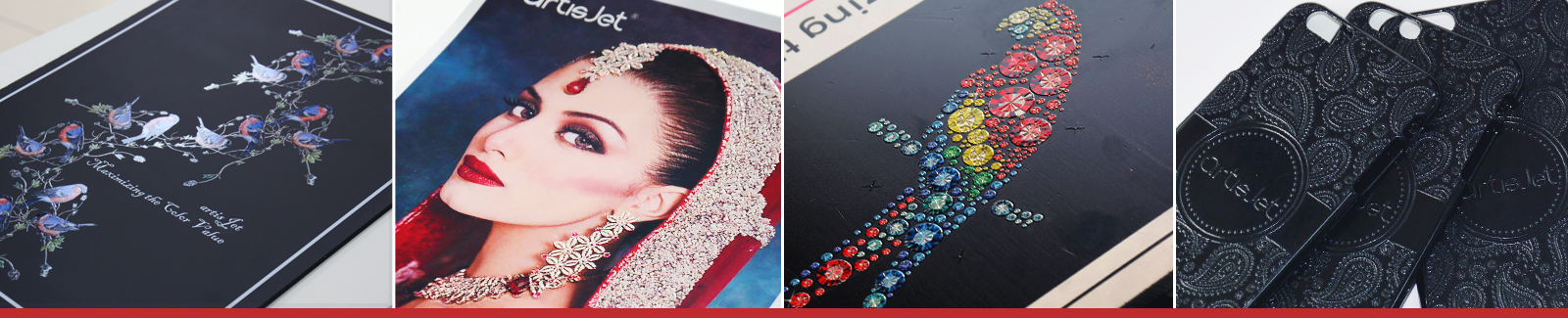

There is a wide variety of specialty printing techniques available for consumers who are interested in setting their printed products apart from the ordinary masses. And that’s the case of Spot LED UV Varnish, a versatile, affordable and high impact printing effect.

UV VARNISH AND SPOT LED UV VARNISH

Is UV Varnish the same thing as Spot LED UV Varnish, or is it something else

altogether?

While many people use the word varnish as a catch-all concept, you must know

there are varnishes (clear inks), aqueous coatings (water-based), and UV

coatings.

UV Varnish is nearly instantly cured by UV light, but usually it fully

covers the substrate, acting as a protective layer.

Spot LED UV Varnish is a clear ink that implies partial

coverage on the chosen spots or area of the printed surface. With the Spot

LED UV varnishing, the

LED UV inks

will highlight specific texts or images, logos, and anything else you want

to drag the attention to.

When the Spot LED UV Varnish is applied, it creates an elegant gloss effect

(or matte effect, depending on the printing needs) which contrasts with the

rest of the printed sheet or substrate and gives an attractive look to the

printed item.

It can be successfully used for wood printing, business cards printing, wedding invitations and wedding cards printing, packaging printing, interior design items such as photo frames and wall decorations, special gift ideas, promotional items, corporate items, gift boxes, cosmetic packaging boxes, luxury paper bags, phone cases, personalized mobile accessories, book covers printing, brand logo printing on boxes to much more. It depends on your ideas, imagination and customer’s requests.

BENEFITS OF SPOT LED UV VARNISH PRINTING WITH ARTISJET

The extensive experience artisJet has gained in the Spot LED UV Varnishing has helped us develop a wide range of printing effects, such as spot gloss, matte varnish, 3D relief with raised varnish, subtle relief, strong printed textures, and scratch-resistant prints even for outdoor items, such as signage printing and door signs.

When the varnished areas are exposed to LED UV light, drying happens almost instantly. This is one of the reasons why the Spot LED UV Varnish application can achieve such a high level of precision.

Digital direct to substrate Spot LED UV Varnish with artisJet is perfect for short runs and even variable data printing. With both flat and raised printing options available, brilliant touchable effects can be created. Add to this, it reduces the set up costs, as it requires no films or screens.

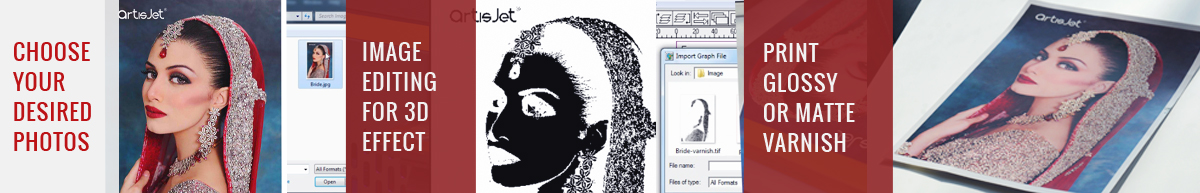

HOW SPOT LED UV VARNISH WORKS WITH ARTIS 5000U PRINTER?

Equipped with artisJet latest technology, Spot Fine Control System, specialized UV Curing firmware and hardware, artis 5000U enables the users to realize the partial print of the image on demand.

Main features include:

1. Flexible varnish printing options. Empowered by artisJet

V.9.0 Print Manager, the user is allowed to select their desired varnish

print result from light effect or matte effect by one click.

2. High standard shinning colors. Raises the color

performance into a higher level and protects the color to extend the print

life.

3. Improved embossed and Braille printing.

4. Additional feature by varnish printing on dark materials.

5. Deliver a diamond printing result on demand.

The Spot LED UV Varnish has the potential to add color depth to the print. Spot LED UV Varnish Printing is characterized by very good running capabilities, easy handling, showing a high mechanical resistance. So when you use it in print projects, it’s a good idea to take into consideration.

Watch the video and learn the easy-to-follow steps of artisRIP software on how to print glossy and matte varnish effects with artis 5000U A2+ LED UV printer.

Want to know more about [Spot LED UV Varnish] with artisJet printers? You

can reach us by several ways:

DM on available main social media platforms:

Facebook,

Instagram,

Twitter, fill in the

contact form

or simply e-mail us by

This email address is being protected from spambots. You need

JavaScript enabled to view it.

.

Feel free to request a sample to discover the spot LED UV varnish printing capabilities with artisJet.

About the event. Sign and Graphic Imaging Middle East Dubai is the largest event of the year in MENA region, bringing together a vast gathering of both exhibitors and visitors from across the UAE, Egypt, Lebanon, Iran, Iraq, India, Pakistan, East Africa and others.

SGI Dubai showcases products and services, and increases businesses interaction with the leading players in the signage, graphic imaging, screen and digital printing.

Some of the approached sectors are: advertising and design, entrepreneurs, designers, contractors, business development, print and production manufacturing, signs to more.

artisJet Direct to Substrate Solutions in SGI Dubai 2018. Some of the artis printing models and its LED UV and DTG technologies will be showcased by artisJet’s partner in Dubai, Masonlite Sign Supplies & Equipments.

Masonlite will display the following renown platforms: artis 2100U A4 LED UV printer, artis 3000U A3+ LED UV printer and artis 3000T A3+ DTG printer. In Stand E-24, Hall 6, Dubai World Trade Center, you will find several printing solutions not only for a simplified operation, but a versatile offer for increased printing workflow: phonecase printing, indoor decoration printing, card printing solutions as well as VDP cards, packaging, direct to textile printing, T-shirt printing to more.

From 14 to 16 January, visit us in Stand E-24 | Hall 6 | Dubai World Trade Center to get onsite details and product information from artisJet representatives. Discover more of what artisJet’s printing technologies and solutions can do for your business.

Check event’s Facebook page and stay updated: SGI Dubai 2018.

About Souvenir Expo Greece. Parousies 2018 is the largest and exclusive trade fair for tourism and folk art items. Organized by ROTA Trade Show Organizing and Souvenir Expo Greece event planner, the 5 day event will be held from 10th to 14th of January 2018 at the Metropolitam Exhibition Center in Athens, Greece.

This event will showcase a wide range of products related to the tourism industry, from gifts items, souvenirs, folk art items etc. The list of exhibits comprises: leather wares, wood carved items, decorative items, silver jewelry, postcards, travel items, beach accessories, sunglasses, fashion accessories, ceramics, watches and much more.

artisJet Greece in Parousies 2018. The all 3 printer sizes of artisJet’s LED UV systems will be on display in Stand A51, Hall 2. artisJet’s partner in Greece, Master Print & Cut Systems, will be waiting for its visitors with already printed applications (mobile covers, custom phone accessories, business cards, PVC cards, indoor decoration items, souvenir printing, gift printing etc.). Among the large variety of printed items, artisJet’s partner in Greece will be exhibiting 3D embossed / Braille printed applications.

The 3D embossed effect, as well as Braille printing and varnish printing, are few of the benefits that artisJet LED UV technology systems have to offer for print on demand custom products, and for start-up or medium-sized personalization businesses.

Be part of Souvenir Expo Greece – Parousies 2018, and meet us in Stand A51, Hall 2 for on-site product demonstration with artis 2100U A4 LED UV printer, artis 3000U A3+ LED UV printer and artis 5000U A2+ production printer. This way, you can see the added value of direct to substrate LED UV printing for the personalization industry.

Souvenir Expo Greece is a great opportunity to build the basis of a printing business with the right tools and solutions. We’ll be waiting for you in Stand A51, 2nd Hall | Metropolitan Expo Center. Stay connected to artisJet Facebook event page for Parousies 2018 updates.

See you in Athens!

Digi Sign Fair overview. Covering sectors such as outdoor advertising, engraving, digital printing, displays, electric signage, graphic imaging industry to more, the International Digital Printing and Advertising Technologies, Materials and Services Trade Fair takes place annually. Next year, the Digi Sign Africa fair will be held from 9 to 11 January 2018 in Cairo International Convention Center, Egypt, reaching its 11th edition.

Digi Sign Africa is an opportunity not only on a regional level, but also for industry related worldwide businesses. As an exhibitor in Digi Sign, you’ll get the opportunity to meet new partners and potential buyers, reach new markets, introduce innovative products and technologies, and keep track of the industrial trends to more.

As a visitor in Digi Sign, the trade fair in Cairo is the source to discover and evaluate the latest technologies, locate new sources of supply, develop beneficial business relationships and expand the network of professionals in the market of Egypt and North Africa, all in one place.

artisJet at Digi Sign 2018. Digi Sign 2018 will set the start of 2018 exhibitions series that artisJet will be part of. At the 2018 edition, artisJet’s LED UV technology will be showcased by its partner, CMYK Print Solutions. During the 3 days of Digi Sign Africa fair, CMYK Print Solutions will display two of the re-known artisJet LED UV printing systems: artis 3000U A3+ LED UV printer and artis 5000U A2+ LED UV production printer.

If you want to know more about artisJet direct to substrate LED UV printing solutions and see the printers in action, we invite you to visit CMYK Print Solutions in Booth B2, Cairo International Convention Center, Egypt, Digi Sign Africa 2018. Stay connected to artisJet Facebook event page for Digi Sign Africa 2018 updates.

WHAT IS VARNISH?

Varnish ink allows you to enhance and protect the quality of the printed image, artwork, text or logo. It’s mainly clear and can be applied either before or after the printing work.

Varnish is considered to be one of the best methods available to enhance the appearance of a printed substrate. You can see the difference once you apply the UV varnish ink and you can add profits to your bottom line.

Direct varnish ink printing offers vibrancy and dramatic colour effect, creating a lasting impression and making your printed applications production more likely to be retained.

Its use brings value in every aspect of the printing industry. Varnish is basically clear ink and can give glossy, satin or matte printing finishes. You can add varnish to the printing area for shiny effect or to highlight specific areas of a printed piece by adding depth to a logo or image.

APPLICATIONS OF DIRECT VARNISH PRINTING

The glossy varnish offers a smooth, shiny and glossy surface of the printed substrate. In the sunshine, the surface reflects light and that is why the printed media has the very bright and lustrous color. A glossy varnish increases the saturation and depth of colors while improving image contrast and adding anti-scratch features.

Moreover, it provides excellent protective quality as well as a raised touchable effect as the 3D embossed effect and Braille tactile effect, often used in direct to signage printing.

A matte varnish is the most popular finish used for printing different products such as wood frames, wood packaging and many more. Using a matte varnish in the case of imagery printing tends to soften the image, giving it a vintage matte look as well as a lush tactile quality to the printing surface.

ARTISJET DIGITAL LED UV VARNISH PRINTING BENEFITS

Varnish can be printed first, as a base for the CMYK colors to ensure color performance and even raised effect. Also, it can be applied after the artwork colors were printed to provide a glossy look or vintage matte finish, depending on what result you aim for.

Believe it or not, varnishing makes easy to clean and handle a LED UV digitally printed image. To sustain this idea, find out that varnishing can offer durable prints by making them water resistant prints. Being able to splash water on a varnish printed item can add value for customers because this way they have the possibility to print applications such as direct LED UV signage printing that can last longer even outdoors.

By varnish printing, the colors appear noticeably richer and vibrant and add the benefit of the fast drying of print on the production line due to LED UV drying process.

Another important feature for varnish printing is that the varnishing is typically cost effective.

No matter the effect you aim to achieve from varnish printing, you have to take advantage of the features from this type of printing and incorporate it to your business. From luxury cardboard / metal / wood packaging to wooden boards used as indoor decorations or multiple types of substrates used as outdoor and indoor signage, as well as direct LED UV printing on phone cases or electronic gadgets and many more, varnish printing with artisJet offers multiple possibilities for your printing business and for your customers.

Got any questions or are you interested in artisJet direct to substrate printing solution for your business? Discover more by sending your inquiries to This email address is being protected from spambots. You need JavaScript enabled to view it. or use the contact form on artisJet website.

You have a favorite printed application sample? Request a sample!

As usual, C!Print Madrid presented new business outcomes and opportunities to the visual communication and personalization sectors. At this year’s event, there were different types of visitors: from companies specialized in object customization to printing and signage companies, as well as visiting companies specialized in interior design / indoor decoration.

artisJet direct to substrate printing solutions and systems. The visitors have shown high interest in the print on demand solutions that artisJet has to offer. From the A4 and A3+ products on display, to the entire range of artisJet printing systems and technologies, the features that raised more interest and attention among the visitors were the better price than other European and worldwide brands, combined with the high quality printing results.

The price component. Pricing is a fundamental aspect when choosing the right LED UV printer. In setting prices, the company that provides the printer will take into account the manufacturing cost, the price at which it could acquire the goods, the market place, competition, market condition, brand, and, of course, the quality of product.

Therefore, regarding the price component, the visitors were attracted also by the price of artisJet consumables. Furthermore, the quality of the prints and the possibility to print 3D effect in different layers amazed the visitors.

Generally speaking, the customers were looking for applications and media such as promotional items, souvenirs and phone case printing. At a first glance, the customers appreciated the physical aspect of the displayed printer models (artis 2100U and artis 3000U), in terms of design and architecture. With artisJet brand they’ve found a better product – price rapport. The best printer is not the most expensive one.

C!Print Madrid was very well visited during all three days and has proven to be once again the biggest of its kind in Spain.

Follow artisJet on social media platforms and constantly visit artisJet website to stay updated for events, printing solutions, new products and printing ideas.

Got any questions? Feel free to send an e-mail to This email address is being protected from spambots. You need JavaScript enabled to view it. or use the contact form.

During the four days-event in Belgrade, Serbia, artisJet showcased two of its re-known direct to substrate LED UV printers, artis 2100U A4 LED UV printer and artis 3000U A3+ LED UV printer.

Besides bringing several already-printed items, artisJet highlighted once again the multitude of possibilities that its LED UV technology has to offer for on demand printing businesses and industry: phone case printing made of acrylic, TPU or leather, as well as PVC cards, customized pen printing and other office stationery, wooden items, book covers etc.

artis printers and media versatility. artis 2100U impressed through its ergonomic design yet both high speed and high resolution printing for an A4 LED UV format printer. Visitors have shown high interest in printer’s capabilities for business card, VDP cards, name badges printing, fridge magnets and other small items.

Moreover, according to the expert jury of the 39th International Trade Fair of Graphic Arts, Paper and Creative Industry – Grafima, artisJet team was awarded the Silver Medal for samples production, especially PVC cards.

Most of the visitors come from industrial printing or souvenir printing domains, but some of the features of artisJet printers which raised more interest and attention among visitors, were the embossed printed samples or varnish printing samples (Braille printing, textured printing on phone cases, glossy effect on PVC cards etc.).

Custom bottle printing. Although artis 3000U printer does not have yet a rotary attachment device (currently available only for artis BR U1800 LED UV model), it still can easily print on square-shaped bottles made of glass or any substrate. The artisJet team made a bottle printing demonstration, while the visitors tested the durability and anti-scratching features of the instant-drying printing results and vivid color output.

Complete printing solutions. In addition to visitors’ high interest in LED UV printing and artisJet LED UV technology, they were happy to find that artisJet can offer blank materials, printing jigs on demand for any kind of media, in order to create a complete printing solution for their requirements.

Page 12 of 17